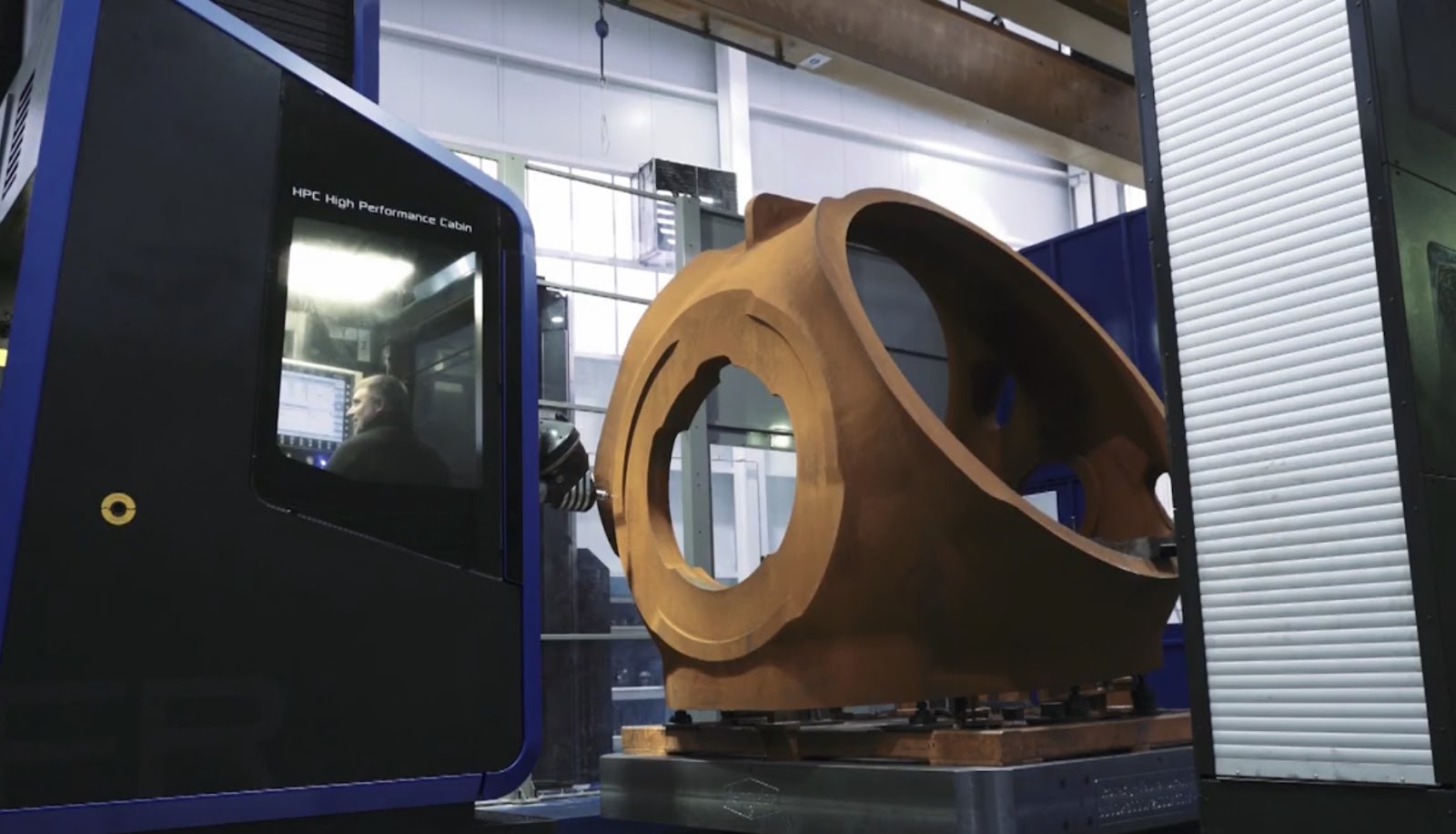

In the realm of industrial machinery, Floor Type Boring Milling Machines are celebrated for their robust structure and multifunctional capabilities. Designed for executing precision tasks on a large scale, these machines are a go-to solution for extensive milling of stationary workpieces. Their distinguishing feature lies in their floor-based design, which ensures enhanced stability and support, especially for handling bulky and oversized items. This unique attribute renders them perfect for various industrial applications.

Distinguishing Characteristics and Technical Aspects

Floor Type Boring Milling Machines are recognized by their substantial size and precision in managing hefty workpieces. Each machine is outfitted with a horizontal boring spindle and a milling head on a movable ram, offering remarkable scope and flexibility. They boast a broad spectrum of spindle speeds, sophisticated CNC controls for meticulous movements, and motors with high torque, fitting for intricate machining operations. Notably, these machines are often equipped with automatic tool changers and rotary tables, further boosting their adaptability.

Versatility Across Industries

These machines are pivotal in sectors where precision and handling of large components are critical. In the aerospace industry, for instance, they play a crucial role in fabricating vital aircraft parts. The energy sector relies on these machines for producing substantial components such as turbine casings. Furthermore, their importance is undeniable in the manufacturing of heavy machinery for use in mining, construction, and transportation.

Operating Strategies and Safety Protocols

Skilled operation and strict adherence to safety standards are imperative for the use of Floor Type Boring Milling Machines. Operators must possess expertise in CNC programming and machine handling. Achieving the desired machining outcomes hinges on precise setup and calibration. Safety practices include consistent inspections, ensuring all protective measures are in place, and compliance with emergency procedures and lock-out/tag-out protocols.

Sustaining Performance and Durability

Maintaining these machines is crucial for their longevity and efficient performance. Regular maintenance involves lubricating moving parts, replacing worn components, and conducting calibration checks. Keeping the machines clean and free from debris is essential to maintain precision and prevent wear. Implementing scheduled downtimes for comprehensive inspections is key to ensuring the machine’s reliability and extended service life.

Emerging Trends in Boring Milling Technology

The trajectory of Floor Type Boring Milling Machines is expected to be influenced by technological advancements in automation and artificial intelligence. The integration of such technologies promises to make these machines more self-reliant, with capabilities for autonomous error detection and correction. Progress in material science may result in the development of machines that are both lighter and more robust, capable of processing a wider array of materials with greater efficiency.

Innovations and Technological Integration in Floor Type Boring Milling Machines

The landscape of Floor Type Boring Milling Machines is continuously being reshaped by groundbreaking innovations and technological advancements. In recent years, these machines have seen significant enhancements, not just in their core functionalities but also in aspects like user interface, energy efficiency, and automation capabilities. One of the most notable advancements is the integration of advanced software and control systems. These systems have transformed the way these machines operate, offering more precise control, reduced manual intervention, and higher consistency in output.

The incorporation of Internet of Things (IoT) technology has brought about a new era in the monitoring and management of these machines. With IoT, real-time data collection and analysis are possible, enabling predictive maintenance and minimizing downtime. This means that potential issues can be identified and addressed before they lead to major breakdowns, thus saving time and resources.

Furthermore, the application of artificial intelligence (AI) and machine learning algorithms is beginning to take root in the operation of Floor Type Boring Milling Machines. AI-driven systems can optimize machining processes, adapt to varying working conditions, and even make autonomous decisions based on real-time data. This leads to improved accuracy, efficiency, and overall performance of the machines.

Another significant development is in the area of environmental sustainability. Newer models are being designed with energy efficiency in mind, contributing to lower carbon footprints in industrial operations. These machines are becoming more efficient in terms of energy use, reducing the overall environmental impact of manufacturing processes.

These technological integrations not only enhance the capabilities of Floor Type Boring Milling Machines but also open new possibilities in manufacturing and production. As these technologies continue to evolve, they promise to bring even more revolutionary changes to the industry, making these machines more intelligent, efficient, and indispensable in modern manufacturing.

Final Thoughts

Floor Type Boring Milling Machines are indispensable in the landscape of modern manufacturing and industrial operations. Their proficiency in managing large, weighty workpieces with exactitude is invaluable in sectors where precision and efficiency are paramount. As technological innovations continue to unfold, these machines are set to evolve, becoming more advanced and competent, thereby augmenting their significance in industrial applications.