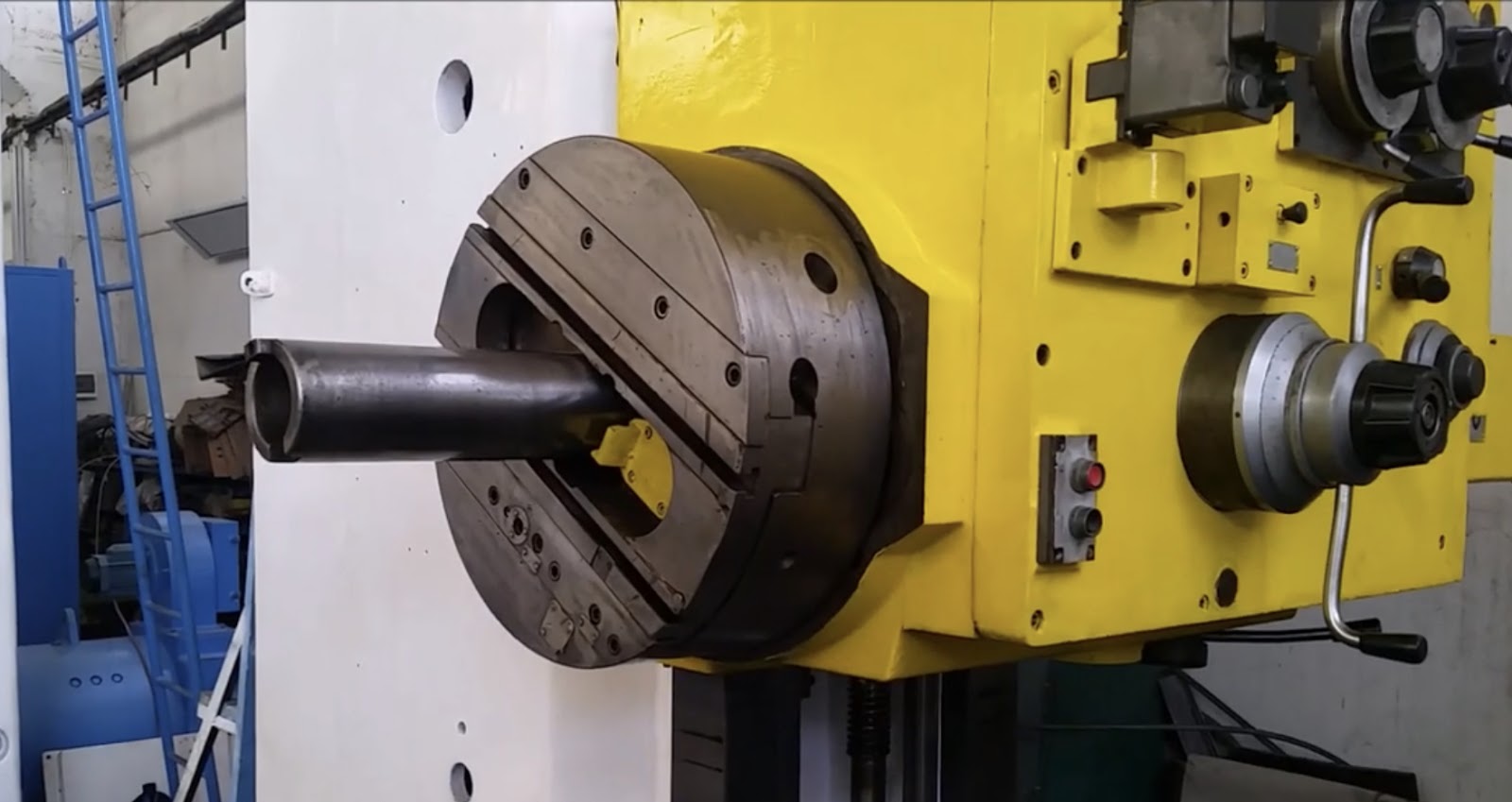

Table Type Boring Machines are integral components in the world of precision machining, offering unparalleled versatility and efficiency. These machines are known for their compact design, which includes a rotatable table that supports the workpiece. This setup is distinct from other boring machines and allows for more intricate and precise operations. Their adaptability makes them suitable for a variety of industrial environments, ranging from small workshops to large manufacturing plants.

Key Characteristics and Capabilities

What sets Table Type Boring Machines apart is their unique combination of size, power, and precision. They are designed to handle both small and medium-sized workpieces, providing high accuracy and control. These machines are characterized by their powerful spindles, advanced digital controls, and ability to perform complex boring operations with ease. Their compatibility with a range of materials, from metals to composites, further adds to their utility in diverse machining tasks.

Industrial Applications and Versatility

Table Type Boring Machines are widely used across various sectors due to their versatility. In the automotive industry, they are essential for creating precise engine components. Aerospace companies rely on them for crafting critical aeronautical parts with exact specifications. Additionally, they are used in the manufacturing of large machinery and equipment for sectors like mining and construction, demonstrating their adaptability to different industrial needs.

Operational Techniques and Efficiency

Effective operation of Table Type Boring Machines involves a blend of skill and knowledge. Operators must understand the intricacies of CNC programming and the mechanical aspects of the machine. Achieving optimal results requires precise setup, careful selection of tools, and meticulous calibration. Emphasizing efficiency, these machines often include features that reduce manual intervention and enhance productivity, such as automated tool changers and programmable rotary tables.

Maintenance and Upkeep for Longevity

To further ensure the longevity and reliability of Table Type Boring Machines, it’s important to adhere to a comprehensive maintenance schedule. This schedule should include not only routine checks but also in-depth inspections of critical components such as the spindle, bearings, and cutting tools. These elements are crucial for the machine’s precision and overall functionality, and any wear or misalignment can significantly affect the machine’s performance. Additionally, it’s vital to monitor the environmental conditions where the machines are housed. Factors such as temperature, humidity, and dust levels can greatly influence the operation and lifespan of the machinery. Implementing climate control measures and maintaining a clean, dust-free environment can prevent many common issues associated with machine degradation.

Training for operators and maintenance staff is another key aspect of ensuring optimal performance. Keeping staff updated on the latest operating procedures, safety protocols, and troubleshooting techniques is essential. This not only helps in preventing mishandling and accidents but also empowers the team to detect and address potential issues proactively.

Furthermore, keeping an inventory of spare parts and essential tools for quick replacements can significantly reduce downtime. Being prepared for quick repairs and having a contingency plan for machine failures ensures continuous operation and productivity. A holistic approach to maintenance, encompassing thorough inspections, environmental management, staff training, and preparedness for repairs, is crucial for maintaining the efficiency, accuracy, and longevity of Table Type Boring Machines.

Technological Advancements and Future Outlook

As technology advances, Table Type Boring Machines are poised to become even more sophisticated. The integration of IoT and AI technologies is expected to enhance their precision and automation capabilities. Future developments might include more intuitive user interfaces, advanced diagnostic tools for predictive maintenance, and increased energy efficiency. These advancements will likely expand the scope of applications for these machines, further solidifying their role in modern manufacturing.

Conclusion

Table Type Boring Machines play a crucial role in the manufacturing and industrial sectors, known for their precision, adaptability, and efficiency. Their continued evolution, driven by technological advancements, promises to enhance their capabilities and applications. As they become more integral to various industrial processes, their impact on productivity and innovation in manufacturing is expected to grow significantly.