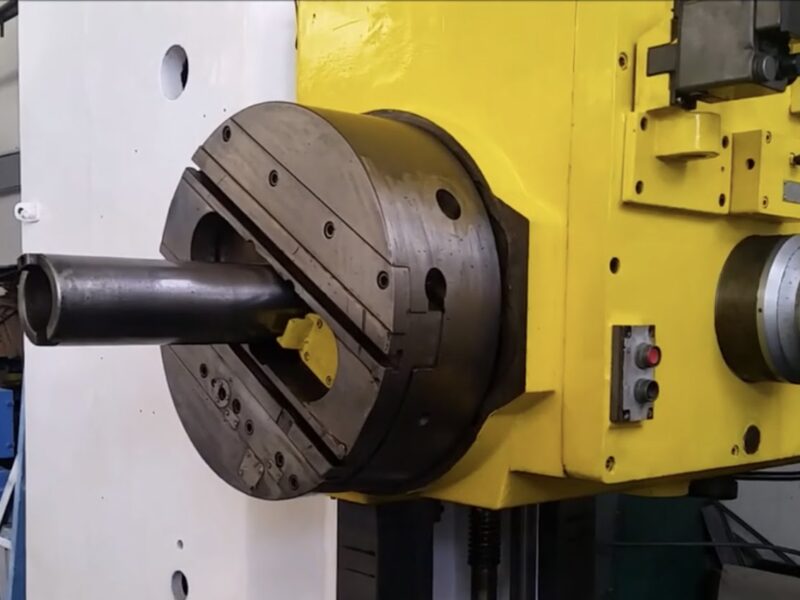

T-Type Boring Machines represent a significant leap in drilling and boring technology. Predominantly used in heavy industries, these machines are designed for large-scale operations, offering unparalleled precision and efficiency. The “T-Type” refers to their distinctive structure, where the horizontal bar, or the ‘T’, supports various cutting and drilling tools. This design is particularly advantageous for handling large workpieces, commonly found in sectors like aerospace, shipping, and large machinery manufacturing.

Key Features and Advancements

The modern T-Type Boring Machine boasts a plethora of features that make it indispensable in industrial settings. One of the key features is its enhanced precision. Equipped with advanced computer numerical control (CNC) systems, these machines can execute complex drilling tasks with exacting accuracy. Additionally, their robust construction allows for handling heavy-duty materials, making them ideal for tasks that involve large metal components. Technological advancements have also led to improved speed and efficiency, reducing operational time significantly while maintaining high-quality outputs.

Applications in Industry

T-Type Boring Machines find applications in a wide range of industries. In construction, they are used for creating precise bores in large structural components. In the energy sector, particularly in oil and gas, these machines play a crucial role in drilling operations, ensuring accurate and efficient extraction processes. The aerospace industry also relies heavily on T-Type Boring Machines for manufacturing parts of aircraft with exact tolerances, where precision is non-negotiable.

Operational Techniques and Best Practices

Operating a T-Type Boring Machine requires skill and knowledge of best practices to ensure both safety and efficiency. Operators must be trained in handling the CNC controls and in understanding the mechanics of the machine. Regular maintenance is key to keeping these machines in top condition. This includes routine checks of the cutting tools, lubrication systems, and ensuring the calibration is precise. Adhering to safety guidelines, such as wearing appropriate protective gear and following operational protocols, is essential to prevent accidents.

The Future of T-Type Boring Machines

The future of T-Type Boring Machines looks promising, with continuous advancements in CNC technology and materials science. Innovations in automation and artificial intelligence are expected to further enhance the capabilities of these machines. This could lead to more intuitive interfaces, predictive maintenance, and even greater precision in drilling operations. Such advancements will likely expand their applications, potentially opening new avenues in sectors like renewable energy and advanced material manufacturing.

Conclusion

T-Type Boring Machines are a testament to the advancements in industrial machinery and technology. Their precision, efficiency, and versatility make them a vital component in various industrial sectors. As technology continues to evolve, these machines are set to become even more integral to industrial operations, driving innovation and efficiency in the manufacturing and construction sectors.