Welcome to the world of precision machining! Jet lathes have gained popularity among craftsmen and hobbyists alike for their outstanding performance and reliability. But have you ever wondered, “Where are Jet lathes made?” In this comprehensive article, we will delve into the origins of Jet lathes, exploring the countries where they are manufactured, the craftsmanship involved, and the factors contributing to their reputation as top-tier machinery.

The Legacy of Jet Lathes

Jet lathes have a rich history that dates back to the mid-1950s. The company behind these remarkable tools, JET Tools, was founded in 1958 in the United States. Initially focusing on innovative metalworking solutions, Jet lathes quickly gained recognition for their precision and quality.

Manufacturing Locations

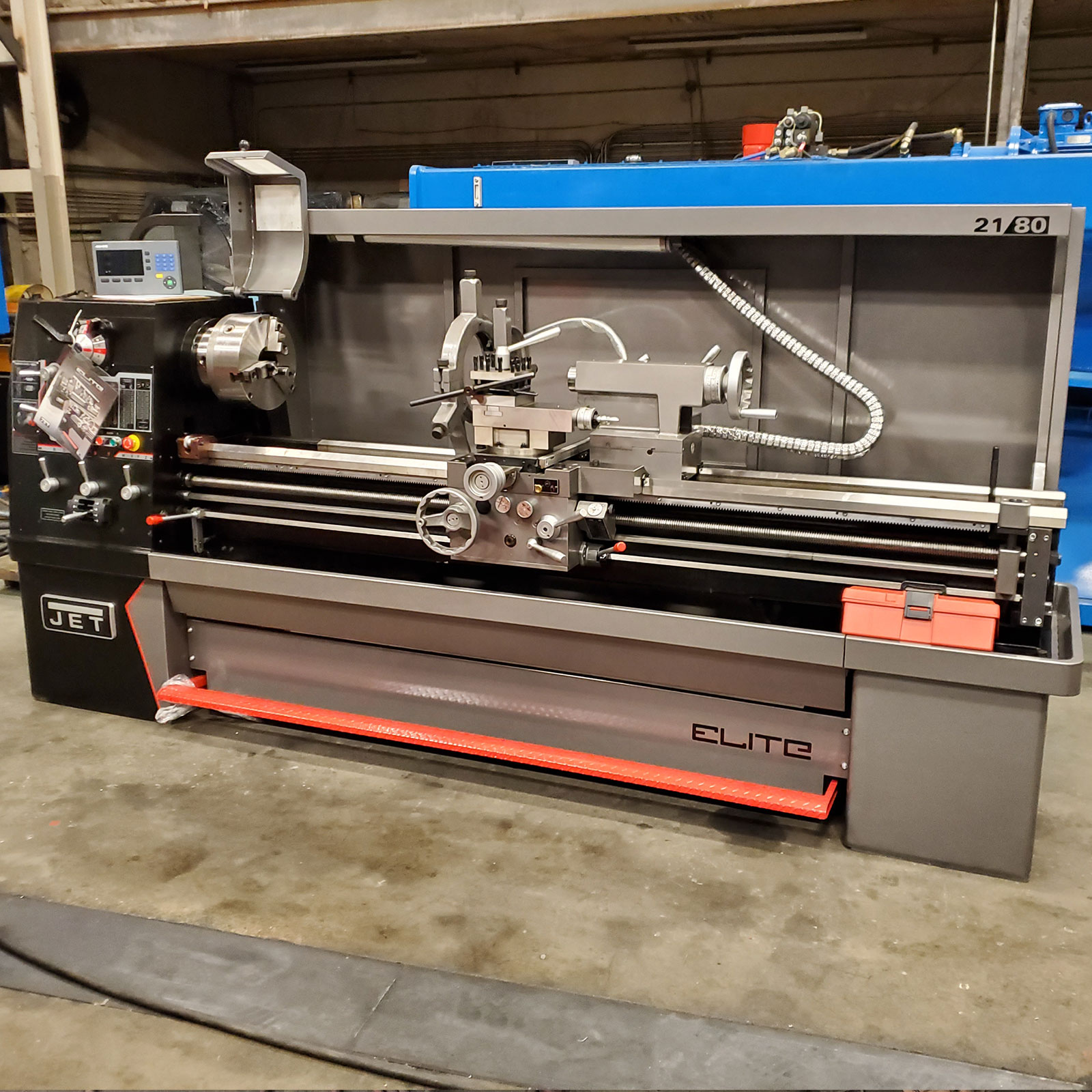

Today, Jet lathes are produced in multiple locations across the globe to meet the growing demand. The primary manufacturing facilities are located in the United States and Asia, with the brand upholding stringent quality control measures in all production centers.

United States Manufacturing

The original Jet lathes are proudly made in the USA, adhering to high manufacturing standards. The company’s American production facilities are equipped with state-of-the-art technology, and skilled craftsmen meticulously craft each lathe, ensuring exceptional precision and performance.

Asian Manufacturing

To cater to the increasing global demand, Jet Tools expanded its manufacturing operations to Asia. Leveraging the expertise of skilled workers and modern facilities, Jet lathes made in Asia continue to meet the brand’s strict quality benchmarks.

The Craftsmanship Behind Jet Lathes

Jet lathes are a result of meticulous craftsmanship combined with cutting-edge technology. Every step of the manufacturing process involves skilled artisans and engineers who are passionate about producing the finest machinery.

Quality Materials

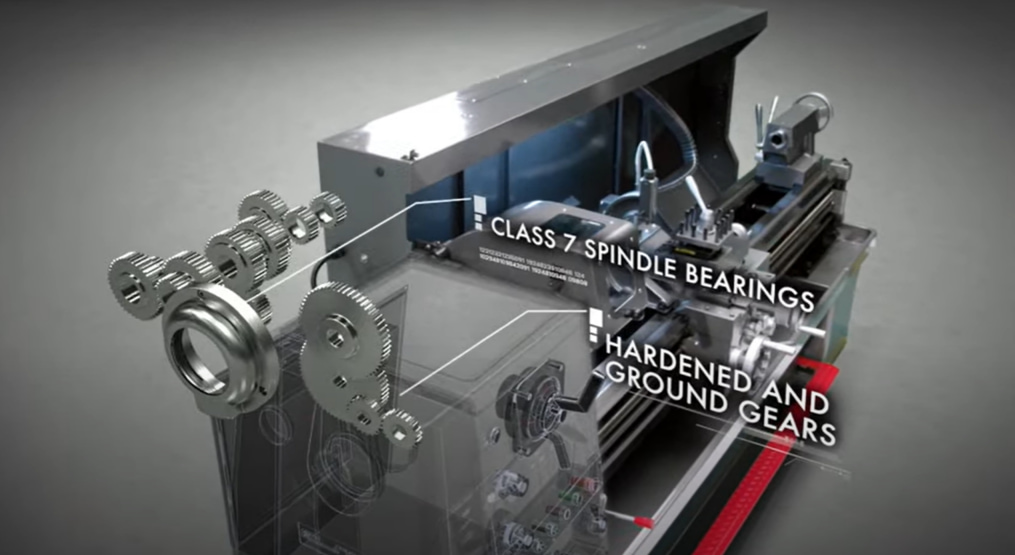

The foundation of any great lathe lies in the materials used to construct it. Jet lathes are crafted from high-quality metals, such as cast iron and steel, to ensure durability and stability during operation.

Precision Engineering

Jet Tools leaves no room for compromises when it comes to precision. Their lathes are engineered with utmost care, incorporating precise measurements and tolerance levels to guarantee smooth and accurate machining results.

Rigorous Testing

Before a Jet lathe reaches the hands of customers, it undergoes rigorous testing and quality checks. Each machine is thoroughly inspected to ensure it meets the brand’s reputation for excellence.

Jet Lathes vs Competing Brands

Jet Lathes

| Feature | Jet Lathes |

|---|---|

| Origin | USA & Asia |

| Materials | High-quality metals |

| Precision Engineering | Unmatched |

| Testing | Rigorous |

Competing Brands

| Brand | Origin | Precision Engineering | Testing |

|---|---|---|---|

| Brand X | USA | High | Standard |

| Brand Y | Germany | Superior | Rigorous |

| Brand Z | China | Moderate | Minimal |

The Popularity of Jet Lathes

Jet lathes have garnered a loyal following due to their exceptional performance, reliability, and customer support.

Customer Testimonials

“I’ve been using Jet lathes for over a decade, and they have never let me down. The precision and smooth operation are unparalleled.” – John D.

“I chose Jet lathes for my woodworking shop, and they have been the backbone of my craftsmanship. Excellent tools!” – Sarah T.

Maintenance and Care Tips for Jet Lathes

To ensure the longevity and optimal performance of your Jet lathe, proper maintenance and care are essential. Follow these tips to keep your lathe in top-notch condition:

Regular Cleaning

Dust, debris, and metal shavings can accumulate on your lathe during operation. Regularly clean the machine, including the chuck, ways, and gears, to prevent any buildup that may affect its functionality.

Lubrication

Proper lubrication is crucial for the smooth operation of your Jet lathe. Follow the manufacturer’s guidelines for lubricating various components, such as the tailstock, tool rest, and lead screw, to reduce friction and extend the life of the lathe.

Belt Tension Adjustment

Ensure that the belts on your Jet lathe are properly tensioned. Loose belts can result in reduced power transmission and vibrations during operation. Regularly check and adjust the tension to maintain optimal performance.

Check for Wear and Tear

Periodically inspect your lathe for signs of wear and tear, such as worn-out gears or damaged parts. Timely identification and replacement of faulty components can prevent further damage and costly repairs.

Jet Lathes: An Investment in Precision

Investing in a Jet lathe is more than just acquiring a piece of machinery; it’s a commitment to precision and craftsmanship. Here are the key reasons why Jet lathes are considered a worthy investment:

Reliability

Jet lathes are renowned for their reliability, making them a trustworthy companion for various machining projects. Whether you’re turning metal or creating intricate wood designs, you can depend on your Jet lathe to deliver consistent results.

Versatility

From professional workshops to hobbyist garages, Jet lathes cater to a wide range of users. They offer versatility in terms of size, capacity, and functionality, allowing users to choose a lathe that suits their specific needs.

Support and Warranty

Jet Tools stands behind the quality of their products by offering excellent customer support and warranties. Knowing that you have reliable assistance in case of any issues provides peace of mind for lathe owners.

Precision and Accuracy

Jet lathes are engineered to deliver precise and accurate results. Whether you’re a seasoned machinist or a beginner, the precision of a Jet lathe will undoubtedly enhance the quality of your work.

Exploring Jet Lathe Accessories and Upgrades

Enhance the capabilities of your Jet lathe with a range of accessories and upgrades designed to optimize performance and efficiency.

Lathe Chucks

Invest in high-quality lathe chucks to securely hold your workpieces in place during machining. Different types of chucks, such as 3-jaw and 4-jaw chucks, offer varying gripping options for versatility.

Tool Rests

Upgrade your lathe’s tool rest to achieve better control and precision during turning. Adjustable tool rests allow you to position your tools at various angles, accommodating different turning techniques.

Digital Readouts

Consider installing digital readouts on your Jet lathe to accurately measure spindle speed, feed rate, and other essential parameters. This upgrade can significantly improve the precision of your machining operations.

Bed Extensions

For larger and more complex projects, bed extensions can increase the capacity of your Jet lathe. With added bed length, you can work on longer workpieces with ease.

Conclusion

In conclusion, Jet lathes have a fascinating history that spans multiple continents. With manufacturing facilities in both the United States and Asia, the brand continues to deliver top-quality lathes that meet the needs of professionals and enthusiasts alike. Their commitment to precision engineering, rigorous testing, and exceptional craftsmanship solidifies Jet lathes’ position as a leading name in the world of machining.