Welcome to the fascinating realm of industrial machinery, where cutting-edge technology and innovation converge to power the world’s industries. In this article, we will embark on a journey to explore the diverse and dynamic world of machines that form the backbone of modern manufacturing, construction, and production processes. From complex automation systems to heavy-duty equipment, join us as we unveil the pivotal role industrial machinery plays in shaping the global economy and revolutionizing the way we live and work. Get ready to delve into the exciting world of machinery and witness the extraordinary feats achieved by these mechanical marvels.

Unleashing the Power of Industrial Machines and Equipment

Industrial machines and equipment form the backbone of large-scale businesses and manufacturing processes, propelling industries to greater heights and capabilities. These mighty giants of engineering are specially designed and tailored to conquer the most demanding tasks, making possible what would be otherwise impractical or even impossible to achieve. Let’s delve into the world of industrial machines and equipment to understand their significance, diverse applications, and the incredible impact they have on our modern society.

Diverse Applications: From Skyscrapers to Oil Rigs

Industrial machines and equipment come into play across various sectors, enhancing productivity and revolutionizing the way we build, manufacture, and extract resources. Here are some key examples of their diverse applications:

Construction Industry: Constructing awe-inspiring skyscrapers or massive infrastructure projects demands exceptional power and precision. Industrial cranes, capable of lifting colossal loads to dizzying heights, are instrumental in erecting these architectural marvels.

Oil and Gas Exploration: Delving deep beneath the Earth’s surface to tap into precious oil reserves requires immense machinery. Industrial oil rigs, with their towering structures and advanced drilling capabilities, are indispensable in this pursuit.

Renewable Energy: As the world shifts towards sustainable energy sources, industrial wind turbines have emerged as a beacon of hope. These towering giants harness the power of the wind to generate electricity on a massive scale, powering entire communities with clean energy.

Types of Industrial Machinery

Industrial machinery encompasses a wide range of equipment used in manufacturing, production, and other industrial processes. Here’s a comprehensive breakdown of different types of industrial machinery:

CNC Machines:

Computer Numerical Control (CNC) machines are automated tools that can be programmed to perform precise machining operations on various materials.

Assembly Lines:

Assembly lines are production systems where products move through a series of workstations, with each station performing a specific task. Components are assembled step by step until the final product is completed. Assembly lines enhance efficiency and consistency in mass production.

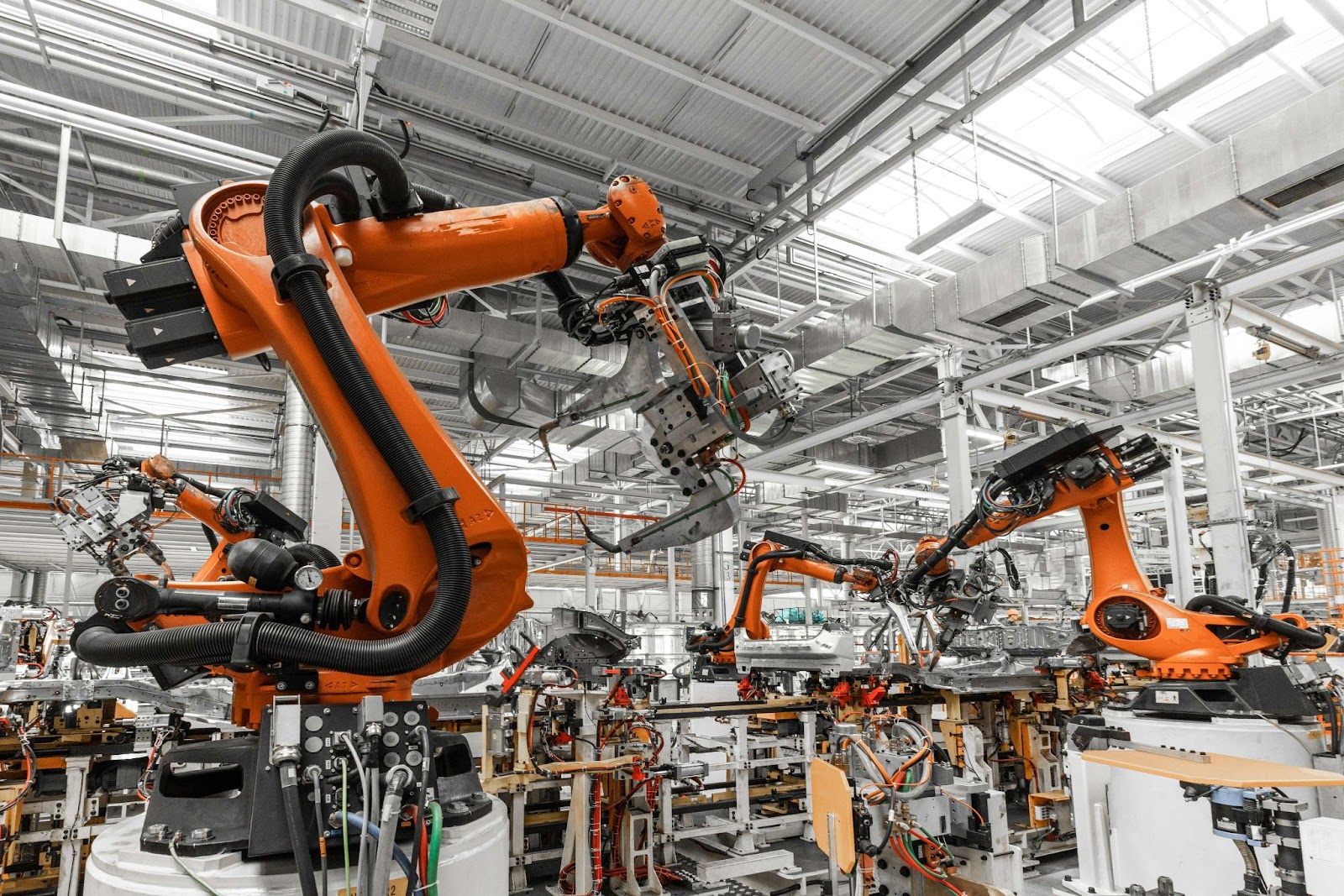

Robotics:

Industrial robots are programmable machines designed to automate tasks within a manufacturing environment. They can handle tasks such as welding, material handling, painting, assembly, and more. Types of industrial robots include articulated robots, SCARA robots, delta robots, and Cartesian robots.

Industrial Ovens:

Industrial ovens are used for various heating processes, such as drying, baking, curing, or annealing materials or products. Types of industrial ovens include:

- Batch Ovens: Load materials or products into the oven for batch processing;

- Conveyor Ovens: Use a conveyor belt to move materials through the heating chamber continuously;

- Tunnel Ovens: Employ a tunnel-like structure for a continuous flow of products through the oven.

Industrial Mixers:

Mixers are used in various industries to blend or combine different materials to create products. Common types include:

- Agitators: Stir liquids or mix components in a tank or vessel;

- Paddle Mixers: Use rotating paddles to blend materials together;

- Ribbon Mixers: Utilize ribbon-shaped agitators for consistent blending.

Industrial Presses:

Industrial presses apply pressure to shape, form, or cut materials. Types of presses include:

- Hydraulic Presses: Use hydraulic power to exert force on the material;

- Mechanical Presses: Operate with mechanical force, often through a crankshaft mechanism;

- Pneumatic Presses: Use compressed air to apply force.

Industrial 3D Printers:

Additive manufacturing machines that create three-dimensional objects by depositing material layer by layer. They are used for rapid prototyping, custom production, and creating complex geometries.

Industrial Saws:

Saws designed for heavy-duty cutting of various materials. Types include band saws, circular saws, and abrasive saws.

Industrial Compressors:

Compressors are used to increase the pressure of gases or air for various applications such as power tools, pneumatic systems, and refrigeration.

Industrial Pumps:

Pumps are used to move fluids (liquids or gases) from one place to another. Types include centrifugal pumps, diaphragm pumps, and positive displacement pumps.

These are just a few examples of the diverse array of industrial machinery used in manufacturing and industrial processes. Each type serves specific purposes, contributing to increased efficiency, precision, and productivity in various industries.

The Significance of Industrial Machines in Heavy Industry

The term “heavy industry” itself denotes the intense nature of the work involved. Heavy industries are characterized by the large-scale production of goods or the extraction of valuable resources, often necessitating robust and rugged machinery. Here’s why industrial machines are so crucial in this context:

- Unparalleled Power: Industrial machines are engineered to handle heavy workloads with ease, offering unparalleled power and efficiency. They can endure continuous operation and withstand the most challenging conditions, making them the workhorses of heavy industry;

- Increased Productivity: With their ability to perform tasks that would be time-consuming and labor-intensive for humans alone, industrial machines significantly boost productivity. They allow industries to meet growing demands and stay competitive in a fast-paced market;

- Enhanced Safety: In hazardous environments or situations that pose risks to human workers, deploying industrial machines ensures enhanced safety. These machines can undertake dangerous tasks, minimizing human exposure to potential dangers.

The Impact on Society and Advancements in Industrial Technology

The prevalence of industrial machines and equipment has undoubtedly transformed modern society and revolutionized the way we live, work, and interact. As technology continues to evolve, the impact of industrial machines keeps growing, leading to remarkable advancements:

- Automation and Robotics: The integration of automation and robotics into industrial machines has redefined manufacturing processes. Autonomous systems now streamline production lines, improving accuracy and reducing human errors;

- Internet of Things (IoT) in Industrial Settings: The IoT has made its way into heavy industry, giving rise to the Industrial Internet of Things (IIoT). Through interconnected sensors and data exchange, industrial machines can be monitored and optimized for maximum efficiency;

- Green Initiatives: In response to environmental concerns, industries are striving for eco-friendly solutions. Advanced industrial machines are now designed with energy efficiency in mind, minimizing waste and reducing their carbon footprint.

Conclusion

In conclusion, the world of machinery in industries is an ever-evolving landscape that promises transformative advancements. From empowering human potential to promoting sustainable practices, the right application of machinery holds the key to unlocking a prosperous and progressive future for industries worldwide. Embracing innovation, fostering collaboration, and upholding ethical standards will be essential in harnessing the full potential of machinery and ensuring a thriving industrial ecosystem for generations to come.